High-performance batteries are at the core of modern technology, from electric vehicles to portable electronics. Producing these batteries at scale requires precise control, efficiency, and consistent quality. Researchers at The University of Texas at Austin, leveraging the resources and expertise of the Texas Materials Institute (TMI), are developing innovative solutions to address key challenges in battery manufacturing. Two recent studies, both published in the Journal of The Electrochemical Society, showcase this leadership.

Improving Critical Steps in Battery Production

Battery manufacturing is a complex, multi-step process where small variations can affect performance, safety, and cost. Additionally, the effect of defects may not be evident in the finished product (battery) for months after use and may lead to catastrophic consequences. UT Austin teams, supported by TMI’s facilities and staff, have focused on two high-impact areas:

- Enhancing Electrode Coating Quality: Led by graduate students Wenlong Li and Ayrton Yanyachi, one study examined how defects arise during the electrode coating process. Using optical, infrared, and X-ray probes, the team demonstrated that each method identifies specific types of defects. Their findings emphasize the value of a multimodal in-line metrology system, a concept enabled by TMI’s advanced characterization capabilities, to ensure consistent, high-quality electrodes. Fine the article at the Journal of The Electrochemical Society.

- Accelerating Electrolyte Wetting: In a second study, graduate students Wenlong Li and Zishuo Zhao developed a method to dramatically speed up electrolyte wetting, one of the slowest steps in battery production. By applying controlled pressure fluctuations, the researchers achieved rapid wetting, inspired by the simple action of squeezing a sponge. This approach, tested using TMI-supported facilities, has the potential to improve manufacturing throughput while maintaining battery performance. Find the article at the Journal of The Electrochemical Society.

Collaboration Across Campus and Industry

These advances reflect UT Austin’s culture of interdisciplinary collaboration, strongly supported by TMI. Faculty mentors Prof. Yijin Liu, Prof. Hadi Khani, Prof. O.A. (DK) Ezekoye, and Dr. Dengguo Wu, director of UT’s Battery Fabrication and Testing Facility, guided the research. Graduate students led experimental design, data analysis, and publication, demonstrating hands-on problem-solving skills.

The projects also benefited from close engagement with industry partners, including Dr. Saravanan Kuppan (Rivian), Dr. Zhao Liu (Thermo Fisher Scientific), and Dr. Jigang Zhou (General Motors), ensuring real-world relevance and impact.

Training the Next Generation

These efforts highlight TMI’s role not only in advancing battery manufacturing research but also in training the next generation of scientists and engineers. Graduate students gained invaluable experience conducting cross-disciplinary research using state-of-the-art TMI facilities.

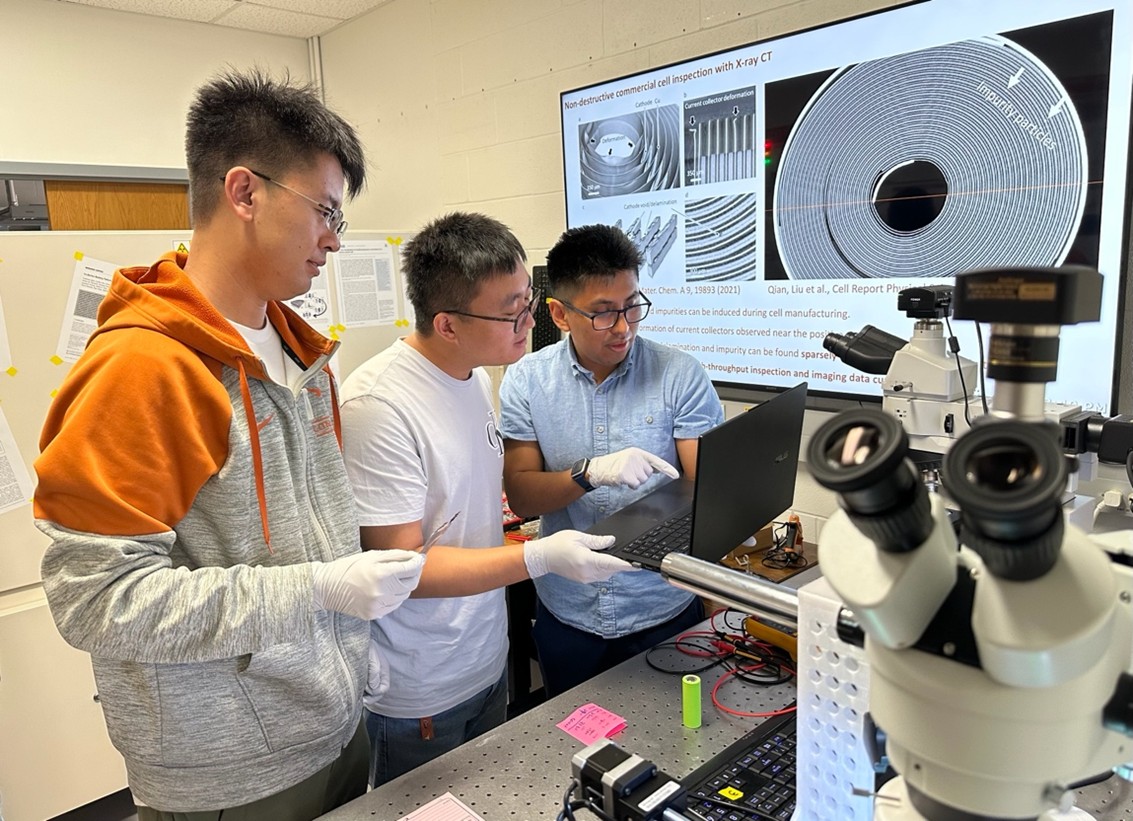

A photo of the student team — Zishuo Zhao, Wenlong Li, and Ayrton Yanyachi — illustrates the collaboration and creativity driving these studies.

Support and Acknowledgments

This research was supported by the National Science Foundation (NSF) and relied on the Texas Materials Institute and UT Austin’s Battery Fabrication and Testing Facility.